Why Smart one?

- We work hard to deliver a solution that fits your budget.

- 24 hours online and a dedicated Account Manager is there to support you.

- Our team has over 20 years experience in all applications.

- 2500 square meter of dust-free workshop and 4 color Heidelberg printer

Best Value

Unmatched Customer Service

Deepest Technical Expertise

Short lead time and Hight quality

What To Pay Attention To Before Making a Smart Chip Card?

When making a smart chip card, customers often have problems such as insufficient preparation or unclear requirements, which can cause the card to be unusable. What should be prepared before the chip card is made, and what issues should be paid attention to during the chip card production process? Let's take a look.

Preparation before printing

The below three issues must be clarified before making the smart chip card. Otherwise, it may not be used normally after the receipt of the new custom smart chip card. If you are not sure, you can directly consult the technicians of our manufacturer.

1. Determine the smart chip card type. Before customizing the smart chip card, first determine the following tips:

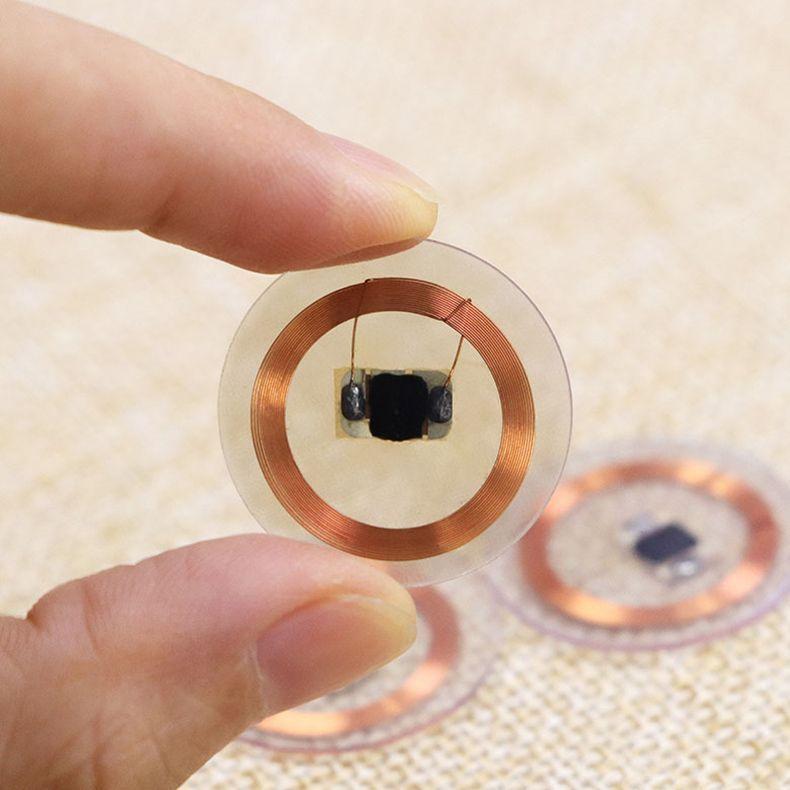

- Do you need an inductive chip card or a contact chip card?

- what is the specific model of the smart chip?

2. Determine whether the smart chip card matches the card reader.

What are the reader models that can be integrated with the software? Because chip card readers need to do secondary development before they can be used. If you have already purchased software, you must first determine which models are integrated with the software of your bought chip card reader, and you must purchase the corresponding model reader.

This card is used before, and the card is provided by the software supplier together with the software. It's necessary to determine whether the smart chip card provided by the software supplier has been encrypted. After the encryption, the new customized chip card cannot be used directly.

Print Content and Embossed Numbers

1. Do you need to print your company logo and text for the smart chip card?

Prepare the logo and the text to be placed on the front and back. You can require our professional designer to design the layout, and our file design is provided for free. After the design is completed, you need to carefully check whether the text, phone number, URL, etc. are correct.

2. Confirm whether the numbers need to be embossed.

It is best not to repeat the number segment and is easy to manage. For example, a 10-digit number can use the first two digits to indicate the year of production, such as the 15 of 1500000001 means that this smart chip card was made in 15 years. The 021 of 021000000001 means that the smart chip card was issued in Shanghai. The following points need to be paid attention to when making embossing codes:

- The position of the embossed code is best to be staggered with the position of the IC chip on the back. Otherwise, the chip will not be recognized.

- The distance between the embossing code and the card edge must be greater than 5mm, The distance between the magnetic stripe (upper and lowe) and the inner frame of the card is 4mm, and the width of the magnetic stripe is 12mm or be customized.

- Small embossing code is 14 font, large embossing code is 18 font, which can be expressed in bold. Small and large embossing code can only contain 19 spaces at most. The embossing code can be hot stamped with gold and silver, and it can be customized for special requirements.

With the increasing use of smart chip cards, the quality of chips is also divided into different levels, such as regular original chips, bulk chips, imitation chips, etc. Some customers and manufacturers will use unstable chips to make cards because they are cheap. In this case, quality problems are prone to occur, resulting in failure to use or quality problems during use. In addition, it is best to find a professional chip card manufacturer to make it, so as to ensure the stability of the factory quality and subsequent warranty issues.